In the production of industrial water and drinking water, the pH value of filtered water is usually required to be in the range of 7-8. However, when using activated carbon filtration process or activated carbon filter element, it is often encountered that the pH value of the filtered water exceeds the standard. This is mainly due to the use of virgin coconut shell or coal-based activated carbon that has not been acid washed or washed.

1.What is virgin activated carbon? Primary activated carbon refers to a porous carbon material made from coal or coconut shells as raw materials and activated by high-temperature water vapor carbonization. It has not been acid washed or washed.

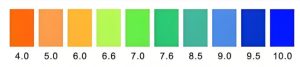

Usually, the pH value of virgin activated carbon is 8-10, or even as high as 8-11. This is because native activated carbon contains a certain amount of sodium carbonate Na2CO3 and potassium carbonate K2CO3. These strong alkaline substances are the main reason why native activated carbon is alkaline.

2.The source of alkaline substances in native activated carbon

The acidity and alkalinity of coconut shells are roughly neutral, and they contain metal ions such as sodium, potassium, calcium, magnesium and aluminum, as well as non-metallic elements such as nitrogen, phosphorus, oxygen and sulfur. During the carbonization and activation process, the compounds of metallic elements are retained because they are non-volatile, while non-metallic elements will escape in the form of gas at high temperatures. For example, sodium nitrate NaNO3 decomposes to release nitrogen and oxygen at 400-600 degrees Celsius. Similar reactions occur with other acid ions, causing these elements to escape from the activated carbon, while the metal elements are present in the activated carbon in the form of carbonates, causing it to become alkaline.

3.How to deal with the alkalinity problem of raw activated carbon.

In order to make the pH value of activated carbon close to neutral, water washing or acid washing is usually used in industry. The pH value of pickled activated carbon can usually be controlled within the range of 5-8, while the pH value of water-washed activated carbon is between 7-8. If you do not choose pickling or water washing due to cost considerations, you can flush the activated carbon tank yourself after installation. Usually using water 300 times the volume of activated carbon can reduce the pH value of activated carbon to about 7-8.

4.The purpose and benefits of pickling treatment. Pickling treatment can not only adjust the pH value of activated carbon, but also has many other benefits:

Reduce heavy metal content: During the pickling process, hydrochloric acid can dissolve and clean out inorganic salts and heavy metal compounds in activated carbon, thereby effectively reducing heavy metal content and improving the safety of water purification.

Adjust the pH value to improve the taste: The pH value of ordinary activated carbon is between 9-11, and the pH value of activated carbon that has been deeply acid washed can be controlled between 7-8.5. The optimal pH value of drinking water is between 7.1-7.6, so the acid-washed activated carbon can neutralize the acidic reverse osmosis (RO) water to generate slightly alkaline water with a better taste.

Remove soluble inorganic salt ash and reduce total dissolved solids (TDS) concentration: Through the pickling process, inorganic salt impurities in several cubic meters of activated carbon can be dissolved, reducing the ash content such as calcium carbonate that affects the taste. The ash content of not acid washed coconut shell charcoal is about 5%, while the ash content of acid washed coconut shell charcoal is less than 3%, and can reach less than 1% after deep acid washed.

5.The difference between water washed and acid washed.

Water washing: Use a large amount of water to rinse activated carbon. The main purpose is to remove dust and some water-soluble substances on the surface. Although this method can reduce the alkalinity of several cubic meters of activated carbon, the effect is limited, and the pH value can usually only be reduced to about 7-8.

Acid washed: Using acidic solutions (such as hydrochloric acid, phosphoric acid) to treat activated carbon can effectively remove alkaline substances and inorganic salts in activated carbon. Pickling treatment can not only significantly reduce the pH value of activated carbon, but also remove heavy metals and other impurities, thereby improving water quality safety.

6.Acid washed treatment operation method

Acid washed treatment usually needs to be carried out in professional equipment. The following are common acid washed steps:

Preparing pickling liquid: Mix hydrochloric acid and water in a certain proportion to prepare pickling liquid. Usually a 10-15% hydrochloric acid solution is used.

Soak activated carbon: Soak the activated carbon in the pickling solution. The soaking time depends on the specific situation, usually from a few hours to a day.

Rinse activated carbon: Rinse the soaked activated carbon with a large amount of dewatered water until the pH value of the solvent reaches a predetermined range.

Dry activated carbon: Dry the rinsed activated carbon for subsequent use.

7.The Importance of PH Value of Activated Carbon

The pH value of activated carbon is one of the important factors affecting water quality. Untreated virgin activated carbon is usually alkaline and may cause the pH value of the filtered water to exceed the standard. Through water washing or acid washed treatment, the pH value of activated carbon can be effectively reduced to make it meet water quality requirements. Acid washed treatment can not only adjust the pH value, but also remove heavy metals and other impurities, improving water safety and taste.